Five weak points in IPM strategies — and how to bolster them.

Integrated Pest Management (IPM) is a hot, if not pesky, topic for cannabis cultivation. It represents some of the largest costs for producers — both operationally (treatments and labor) and in direct yield losses (pest/disease impact). And at the same time, favorable lab results and minimal crop losses are critical in an increasingly competitive cannabis industry.

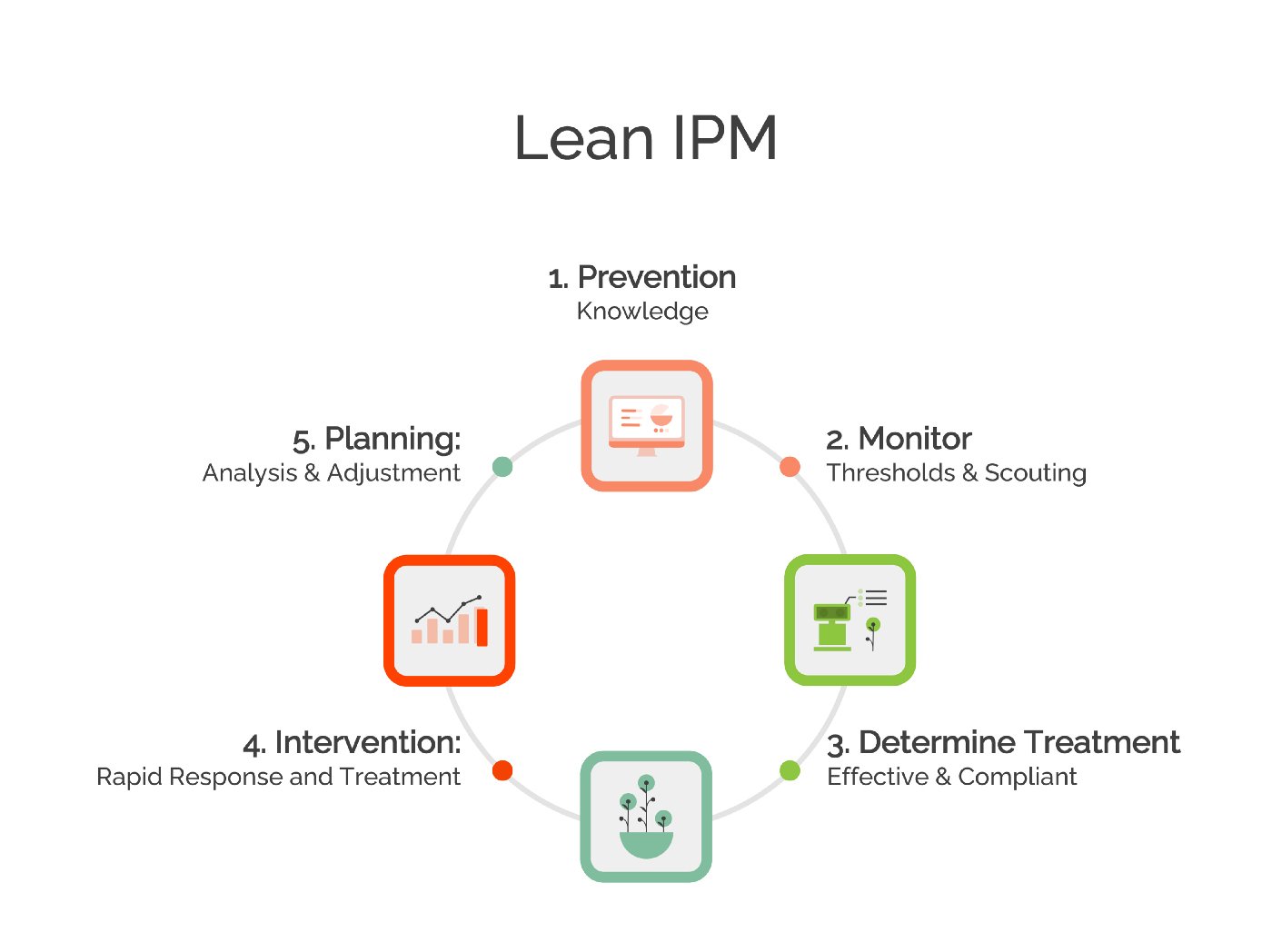

Source: MJResearchCo.com

Managing pests and diseases is a round-the-clock effort and a single tactic is never enough — there is no magic bullet. Instead, IPM is a 5 part process, from prevention through treatment and ending in analysis. This holistic view should be thought of as a chain of defense — one weak link makes the whole chain susceptible to failure.

Cultivators who want to boost IPM effectiveness need to drill into each link in the chain to identify which strategies to scale and which weaknesses to address. For large cultivations with complex operations, the most effective way to do this is by mixing human effort with real-time monitoring & on-going data collection.

In this article, we’re looking at each link of the chain and identifying how cultivators can use data and monitoring to bolster efforts and more effectively manage pest and disease.

Step 1: Prevention

Operators understand that tackling IPM starts with prevention. Maintaining optimal environments is one of the most effective paths to happy plants and large yields. But like the cannabis plant itself, putting these efforts into practice is complex and often requires trial and error as pests and pathogens often flourish in the same conditions we wish to create for the plants.

For example, cultivators know de-leafing is important for airflow and preventing emergence of pathogens and spread of pests. But do you know exactly how much is effective for each genetic variation? Cultivators know that excess humidity and suboptimal temperature can cause the growth of disease. But are they measuring air and leaf temperature at each individual plant?

To maximize yields, operators must speed up this information loop through the collection of more granular data. In many cases, this process is manual, relying on seasoned cultivators who use their expertise and time to monitor conditions and make important decisions. Sometimes they are optimal, but sometimes they’re not. And when not manual, operators incur significant capital expenditures to deploy enough sensors across the crop to get plant-level resolution. Regardless, this objective is hard to scale across a large operation.

Instead, cultivators are utilizing mobile, high-resolution cameras, and sensors to capture granular, accurate data across more square feet. These cultivators then turn to lean cultivation methodology, which focuses on rapidly iterating and continually-improving efficiency through the analysis of high-quality environmental, genetic, process and plant health data. These tools amplify and scale the efforts of IPM staff, using past data and outcomes to suggest prevention strategies.

As cultivation operations grow in size, being able to collect data at scale, learn and adjust in real-time is critical to true prevention.

Step 2: Monitor with Thresholds & Scouting

Cultivators know that living with pests and diseases comes with the territory. This is why the discussion is around “management” and not “elimination”. Realistic and effective thresholds for pest and disease help cultivators to stay focused on the end goal — minimizing losses and producing quality products. Sometimes issues which seem to appear out of nowhere or spread before they can be contained, taking out multiple plants or even full crops. This is usually the result of an issue with setting appropriate thresholds, objectively communicating those thresholds or effective scouting.

Setting & Communicating Thresholds

Subjectivity should be the enemy of any commercial cultivation focused on efficient production. Operators who want to ensure that pest and disease is managed consistently and completely need to ensure they’re properly defining & communicating thresholds. This requires objective data.

Modern tools now give cultivation operations the ability to visually capture and quickly communicate objective standards for pest and disease, making it easier to scale operations. And in some cases, operators can remotely monitor teams and crops in real-time, resulting in quick and effective decision making while saving resources. These tools work well in an industry with high turnover, expansive canopies and insufficient labor. By recording institutional knowledge of acceptable thresholds, operators can better align and equip their team.

Scouting

Missing pest and disease issues is a common problem in large, commercial cultivations where scouting is done exclusively by humans. And even one missed leaf can drastically impact a crop.

Even with objective communication tools, humans are prone to subjective analysis, error and visual fatigue. Adding in digital tools to aid in scouting adds an additional layer of protection, helping cultivators fill the gaps. New technologies rely on cameras, multispectral and thermal sensors to capture high resolution, plant-level data. Machine vision and artificial intelligence systems integrate that data, often catching what employees may have missed (or just not gotten to today). And functionalities like plant-level SMS notifications categorize severity level and integrate with supply chains for proactive ordering, reducing the burden on your team.

Step 3: Determine Effective & Compliant Treatment

The continued federal prohibition and strict regulation of cannabis makes treating pest and disease particularly complicated. Low thresholds for microbials and contaminants in testing, and a slow-moving EPA, mean that many of the common treatments are unavailable for cannabis cultivators.

Operators are faced with a choice on how to tackle issues. Some opt for organic options like beneficial bugs and organic fungicides. While unlikely the product will fail testing, these options have limited efficacy, leading to crop loss. Alternatively, over-treatment (i.e., spraying) can stress or damage the plant. In the end, the result can be the same. Other operators may use conventional agricultural products, hoping they can flush out any chemicals before the product goes to testing — but this is playing with fire. Some use remediation products upon harvest, though there is still much unknown about how these solutions impact quality, terpenes and cannabinoids.

This part of the IPM chain is arguably the most frustrating as unrealistic regulation ties the hands of operators. To offset this, cultivators should use historical data-based recommendations for treatment. New technologies, such as digital scouting platforms, phermones sensors, automated camera traps, in-field spectrometers and spray timing tools, allow operators to track individual plant data — considering plant characteristics, symptoms and treatments and recording outcomes. This complete data set then works together to provide smarter recommendations for treatment type, amount and location, eliminating the need for trial and error.

Operators who find this piece to be the weak link in the chain should look to technology to bolster their efforts.

Step 4: Intervene with Rapid Response and Treatment

So you’ve set and communicated objective thresholds, instituted smart scouting and optimized treatment plans. But you’re still having issues. We need to begin to close the loop and reduce waste in the system by optimizing the speed to treatment, or how quickly your IPM team addresses issues.

Because this piece of the chain hinges upon human effort, IPM leaders should look to boost visibility into task completion.

Digital tools that enable horizontal visibility across the organization can support this effort. In any cultivation, things get busy and priorities get miscommunicated. Tools that enable transparent task setting minimize these issues — that is, we can minimize constant fire drills and focus leadership time on value-add tasks and planning decisions. Tools that give managers the ability to quickly assign tasks & prioritization functionalities eliminate guesswork about what needs to happen when and reduces the likelihood that a pest treatment is delayed or missed.

Operators interested in digital tools to manage their labor force should look for those with visibility at a granular level. These systems set prioritization and help operators see how individual employees are tackling tasks, highlighting where their team may need support and uncovering top talent that can be promoted or scaled.

How a California cultivator reduced losses by 50% with a rapid detect and respond workflow

Step 5: Planning with Analysis & Adjustment

The on-going struggle with IPM is a constantly moving target, hinging on the complex biological systems of plants, fungi, viroids, bacteria and insects. But, if you’re going to experience pest & disease, you might as well learn from it and let it guide better approaches, treatments and outcomes.

The last link in the IPM chain is to plan with analysis and adjustment — the hallmark of continual improvement. And if your operation continues to experience the same issues over and over, this may be your weak link.

This phase is particularly important for setting preventative measures and thresholds. By tracking what was done at each point in the plant’s life cycle against outcomes, we gain insight into how our processes stood up.

Operators focusing on this part of their cycle should focus on two important pieces:

Accurate and real-time monitoring of what is happening. The more granular the information, the more likely you are to uncover root causes and adjust effectively.

The ability to record and scale best practices and effective strategies. Digital tools which enable the communication of objective and consistent information help to coordinate efforts and achieve greater efficiencies.

For more on rapid analysis and adjustment, we suggest learning about Lean Cultivation™ .

Conclusion

Successful operations are not those who claim to have zero IPM challenges. They are those who can answer the question “where did we go wrong, what got us back on track and how can we continually get sharper, quicker and better?”. And then scale those efforts.

By reviewing each link of the IPM loop, cultivators can uncover root causes of IPM and drill into solutions. Innovative, cannabis-specific, tools help to amplify the efforts of the entire IPM team, making sense of the myriad of data points collected in a grow. They also offer more transparency, support behavioral shifts and help teams better coordinate, communicate and control processes.

Pest and disease is a complex issue. But with a combination of human effort and smart tools, operators can optimize crop yields.